Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

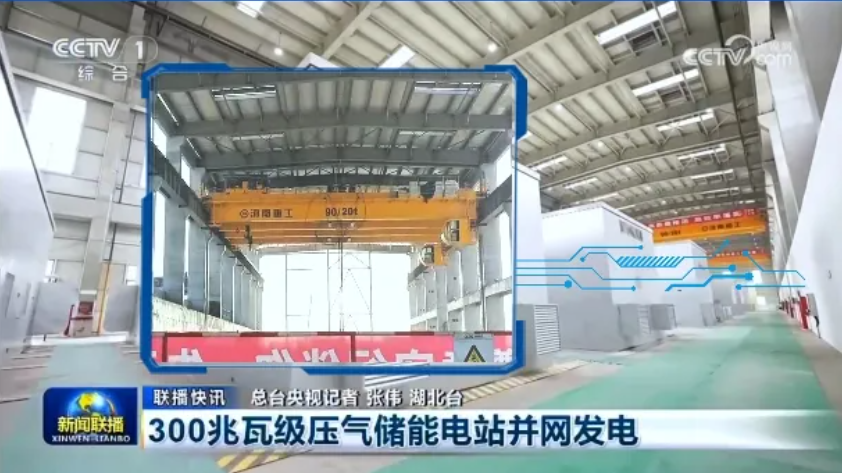

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In modern industrial production, the storage and transportation of products cannot be separated from lifting operations. Motorized hoists provide great convenience for lifting operations and greatly improve work efficiency.

In recent years, the installation and use of motorized hoists are increasing rapidly, and the failures of hoists are also increasing. Maintenance and repair have become particularly important. In particular, the installation and utilization of double hoist overhead crane have amplified the significance of managing the various faults that could occur during operations. Therefore, addressing these problems in a timely and efficient manner is crucial to ensuring the smooth running of production.

Electrical part

The handle switch and the component that users contact the most. Check whether the switch and the shell are intact. The control box hanging outside the hoist should be clean with no peculiar smell. Check whether the main control power supply and cable are normal.

If the shell is cracked and the button falls off, the handle should be replaced in time. The temperature inside the control box should not be too high. If the motorized hoist has a high temperature or ignition phenomenon, it should be immediately stopped for inspection to avoid accidents.

Mechanical part

Check whether the transmission part of the lifting motor is normal, whether the reducer has sufficient oil, and whether the motor walking wheel is fully engaged in the steel beam. If the transmission is uneven, and the load slips when the hoist is parked at a high position, check whether the crane brake is too tight or whether there is a loose phenomenon.

Load lifting part

Check whether the wire rope is oiled, whether there are burrs, whether the guide rope is on the normal track, whether the winding wire rope has a jumping phenomenon, and whether the hook is flexible.

Electrical failure of the motorized hoist

The motorized hoist does not work when the starting switch is turned on.

Generally, there are three situations why the hoist is unable to work. First, the motorized hoist main power supply is not connected. This can be determined with a test pencil. Connect the main power supply to the hoist. Second, the handle switch is faulty. The hoist handle is generally divided into remote control handle and cable-pull handle. When the start button of the remote control handle does not respond, first check whether the handle battery has power, whether the induction key is turned on, and whether the handle is within the remote control range. For the cable-pull handle, it is usually naturally suspended when not in use. When the crane button does not respond, first check whether the emergency stop button is pressed. If pressed, it needs to be reset. Secondly, check whether the wire head inside the handle is loose. If the connection is good, check whether the junction box inside is normal. If there is an adhesive contact or defect in the junction box, just replace the contactor.

If the terminal voltage of motorized hoist is more than 10% lower than the rated voltage, the starting torque of the motor is too small, making it impossible to lift the load and work.

When checking, use a multimeter or voltmeter to measure the input voltage of the motor. If the motor cannot start due to low voltage, the motorized hoist should be used after the system voltage returns to normal. Sometimes the voltage of the motorized hoist is normal, but the EOTC crane still does not work. Other reasons should be considered in this case.

Mechanical failure of the motorized hoist

Bearing damage

Bearing damage produces a "clang-clang" sound near the bearing; when the shaft center of the coupling is not correct or the motor slightly runs, the entire crane motor emits an extremely high-frequency "whining" sound, which is sometimes accompanied by a sharp, piercing sound.

The fault should be found based on the different noises, and repaired step by step to restore the normal performance of the motor. When the motor is faulty, the hoist should not be used.

Reducer failure

When abnormal noise appears near the reducer, the crane should be immediately stopped to check whether the reducer or bearing lacks lubricating oil, gear wear or damage, and bearing damage.

First, determine whether the gearbox or bearing of the reducer has been lubricated before use or whether the lubricating oil has been replaced regularly during use. If it is not lubricated as required, the reducer will not only produce high-frequency "whining" sound but also excessively wear or damage gears and bearings. If the gear of the crane reducer is excessively worn or damaged or the reducer bearing is damaged, it needs to be disassembled and repaired or replaced immediately to eliminate the fault and reduce the noise.

Lifting protection

During the trial lifting, the hoist automatically stops, and it cannot continue to lift but can normally descend; this is because the overload protector is installed on the lifting wire rope, and the lifting load exceeds the rated load. In this case, it is only necessary to reduce the lifting load of the crane, and there is no need to carry out fault diagnosis. If the load is within the protection range, it is necessary to calibrate the protection value.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259