Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

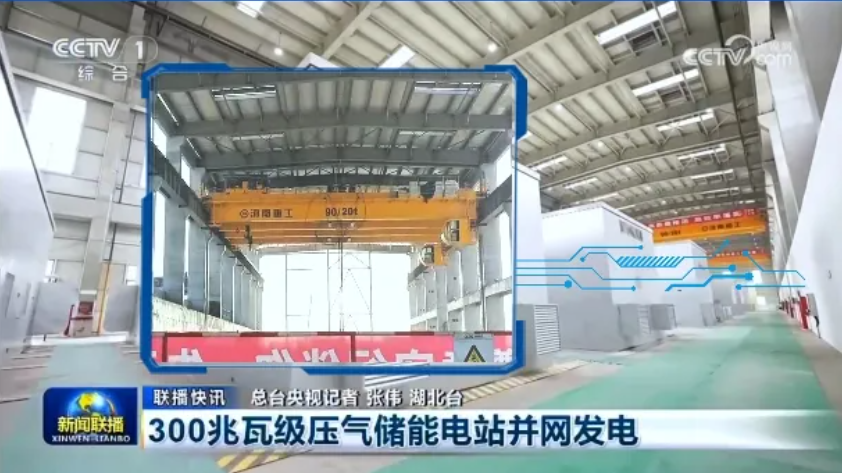

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

The hoist manufacturers believe that doing a good job in crane maintenance during the inspection interval is the basis for ensuring the normal and continuous operation of the hoist crane. Correctly doing the maintenance work during the inspection and repair period can extend the inspection interval, reduce the workload of the inspection and improve the equipment productivity.

1. Primary maintenance: It is a regular maintenance work, which is the responsibility of hoist crane operators, which mainly includes inspection, lubrication, tightening and adjustment of wire ropes, drums, pulleys, bearings, couplings, reducers, eot crane brakes and so on.

2. Secondary maintenance: It is the regular maintenance work, which is taken care of by the maintenance workers, including the maintenance and maintenance of the entire hoist crane's various institutions and equipment.

In order to ensure the safe operation of the hoist crane, the first task is to do a good job in the inspection of the hoist crane.

1. Daily inspection of hoist crane

This item is carried out in conjunction with the shift system of hoist crane operators. The hoist crane operators who shift shifts are mainly responsible for the important mechanical and electrical components of the hoist crane, such as hooks, wire ropes, eot crane brakes of various mechanisms, controllers, stoppers of various mechanisms, and various Check whether the safety switch is sensitive and reliable. The specific inspection items are as follows:

(1) Check whether the main power switch of the hoist crane protection box has been cut off, and it is strictly forbidden to check with power.

(2) Whether the steel crane pendant wire rope has broken strands or broken wires, whether the winding of the drum and pulley is normal, whether there is no groove, knotting, twisting, etc., and whether the pressure plate bolts at the end of the steel rope are fastened.

(3) Whether the hoist crane hook is cracked, whether the anti-loosening device of the hook nut is complete, and whether the spreader is complete and reliable.

(4) The hoist crane checks whether the movement of the end limit switch is flexible and normal, and whether the movement of the safety protection switch is flexible and working normally.

(4) Whether the rotation of each mechanism of the hoist crane is normal, and whether there is abnormal sound.

2. Establish a responsibility system and appraisal system for hoist crane equipment

(1) In order to ensure that the daily maintenance of hoist crane equipment is implemented, each unit should establish a job responsibility system for fixed machines and personnel. The advantages of the fixed machine and personnel position responsibility system are as follows.

(2) It is convenient to strengthen the operator's sense of responsibility, and strengthen the operator's sense of responsibility for the correct use and careful maintenance of the equipment.

3. It is convenient to carry out the competition for the maintenance of hoist crane equipment, improve the intact rate of the equipment, keep the equipment in good condition, and operate by dedicated personnel so that the operator can understand the peculiarities and defects of the equipment. Then, the using potential of the equipment can be fully utilized. One person is responsible for the maintenance of the hosit crane he used. Cranes operated by several people in shifts are maintained by each shift. Once the fixed-person and fixed-machine system is determined, random changes are not allowed. If changes are needed due to special circumstances, the operator should be approved by the leader and can only operate after completing the change procedures. The enterprise should check and evaluate the maintenance status of the hoist crane according to different situations. Some competition activities are of great significance to extend the service life of equipment and ensure safe production.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259