Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

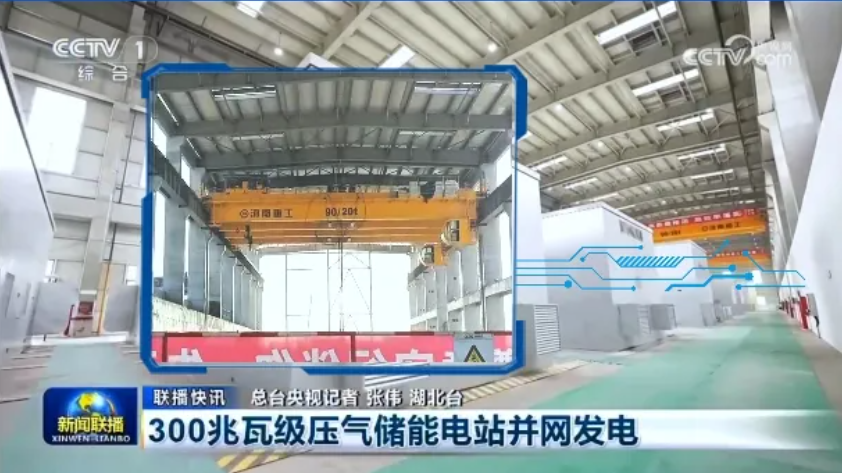

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

Currently, the most widely used lifting equipment in ports is the harbor crane, which is generally used outdoors and requires maintenance due to frequent exposure to wind and rain. It is necessary to regularly replace vulnerable and corroded parts.

Harbor cranes promote the development of port economy and improve port operation efficiency.

The lifting mechanism is an important component of the quay crane, consisting of a hoisting motor, reducer, drum, brake hook and the like. The hoisting motor is connected to the reducer through a coupling, brake wheel and reducer. The output shaft of the reducer is connected to the steel wire rope drum, and the other end of the steel wire rope is equipped with a hook. When the drum rotates, the steel wire rope winds or loosens on the drum, leading to the movement of the hoist. The hoisting motor of the hoisting mechanism retrieves the item from the starting position at the rated speed. The lifting speed generally does not exceed 30m/min and should be decided based on the nature, weight, and lifting requirements of the goods.

The speed of the hoisting mechanism is related to the lubrication status of the motor, reducer, drum, brake, hook, and equipment. The speed depends on the size and weight of the hoist. However, it must be emphasized that safety comes first under all circumstances.

When it comes to harbor crane operations, different crane grab bucket types are necessary for the effective and efficient transportation of various materials. There are many types of grabs on the platform of harbor cranes, and they are suitable for grabbing various materials. However, the type of the grab should be selected according to the nature of the material and the operating environment to effectively and stably complete the transportation of materials.

Composition of the grab

Generally speaking, the system can be divided into two parts, one is the fighting part, and the other is the host part. In the host part, crawler cranes are generally used as the main engine of the grabs.

However, even if a crawler crane is determined, there are still different configuration requirements; hydraulic grabs should increase the hydraulic system.

In addition, the grab adopts a single-strand shaft cylinder body design, which has the characteristics of simple overall structure, large grabbing ratio, strong closing force, and high material filling rate. According to certain special requirements, dust covers and blade seals can be designed for the grabs to protect the grabs and materials from being affected as much as possible.

Auxiliary functions of the grab

In addition to the basic grabbing function, many grabs are also equipped with tilt gauges and anti-tilting devices, which can identify and correct the inclination of the bucket body through sensors and hydraulic systems to ensure stable material grabbing and reduce accidents.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259