Euro Double Girder Crane for Inner Mongolia Energy Group Project

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

ZHONGGONG supplies a full range of components and parts for cranes and hoists, such as crane motors, crane brakes, wire rope, crane reducer, crane gearbox, etc. The general bridge crane is composed of bridge running mechanism, crane trolley and bridge metal structure. The lifting trolley is composed of hoisting mechanism, trolley operating mechanism and trolley frame.

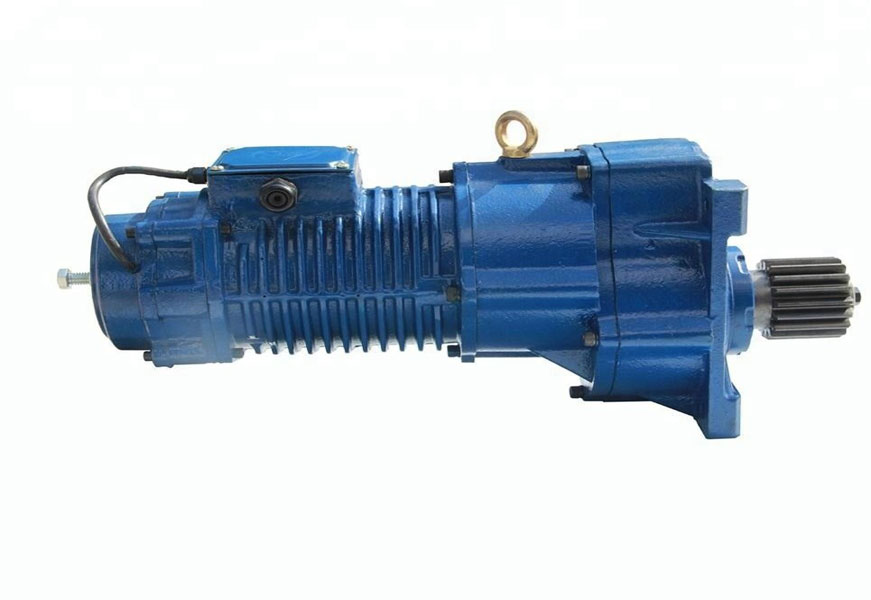

Crane Reducer | It is to reduce the high speed of the motor to the working speed required by each mechanism. |

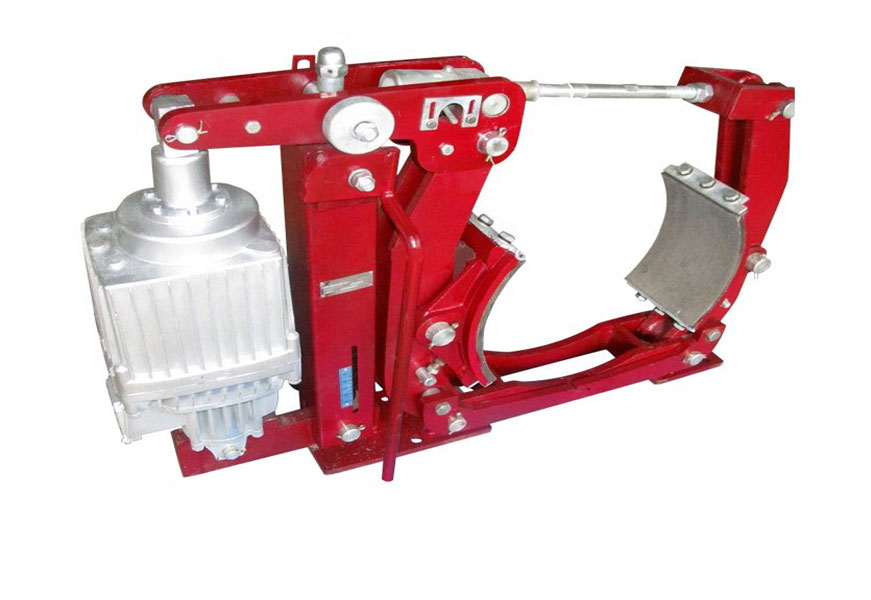

Crane Brake | It is generally installed on the high-speed shaft of the mechanism to reduce the braking torque. |

Crane Wheel | Crane wheels are for sustaining the crane. The wheel and the angle bearing housing are assembled together to form a wheel group. |

Wire Rope | It’s constituted by steel wire, rope core and grease.Lifting, towing, straining and load bearing |

Roiling Drum | It is a part of the hoisting mechanism used to wind the steel wire rope. |

Crane Hook | Crane wheels are for sustaining the crane. The wheel and the angle bearing housing are assembled together to form a wheel group. |

Grab Bucket | It’s constituted by steel wire, rope core and grease.Lifting, towing, straining and load bearing |

Crane Rail | It is a part of the hoisting mechanism used to wind the steel wire rope. |

Crane Cabin | It is a crane operator room with console for crane control. |

Crane Motor | For your different needs, we provide crane motors of various well-know brands. |

Crane Electromagnetic Chuck | We offers types of electromagnetic with different sizes to meet various needs of your electromagnetic overhead cranes. |

Control Pendants | Crane control handles can be a wire pendant, wireless remote control, joystick control, or radio control. |

Overload Limiter | Simple structure, quick action, safe and reliable, automatically control. |

Wire Rope Pulle | It is divided into fixed pulley and movable pulley block. |

Gear Motor | The gear motor is a 3-in-1 drive equipment which combines motor, reducer/gear box and brake into one machine. |

The lifting mechanism includes brake, motor, reducer, drum and pulley block. The motor drives the drum to rotate through the reducer, so that the steel wire rope can be wound on or put down from the drum to lift the weight.Trolley frame is a frame supporting and installing hoisting mechanism, trolley running mechanism and other components, usually of welded structure.

The driving modes of crane operating mechanism can be divided into centralized driving and separate driving. Small and medium-sized bridge cranes mostly adopt the "three in one" driving mode composed of brake, reducer and motor. In order to facilitate installation and adjustment, the driving device of ordinary bridge cranes with large lifting capacity often adopts universal coupling.

The bridge is composed of main beam and end beam, which is divided into single main beam bridge and double beam bridge. The main beam is rigidly connected with the end beam, and wheels are installed at both ends of the end beam to support the bridge to run on the elevated. A track is welded on the main beam for the operation of the lifting trolley.

Safety inspection for eight general crane spare parts:

1. Hook. Check whether the marking and anti falling off device of the hook meet the requirements, and whether the hook has cracks, peeling and other defects; Whether the wear of hook section, the increase of opening degree and torsional deformation exceed the standard; Whether the neck and surface of the hook have fatigue deformation, crack and wear of relevant pin shaft and sleeve.

2. Wire rope. It is necessary to check whether the specification and model of steel wire rope match the pulley drum and meet the design requirements. Whether the pressing plate, rope clamp, wedge and other wire rope fixing devices at the fixed end of the wire rope meet the requirements. Whether the wear, broken wire, kink, flattening, bending, broken strand and corrosion of steel wire rope exceed the standard.

3. Braking device. The brake pad shall be free of burning and burnt smell, and the friction surface of the brake wheel shall be free of oil stain.

4. Reel. Whether there are fatigue cracks and damages on the drum body and drum edge; Whether the wear of rope groove and barrel wall exceeds the standard; Whether the height of the drum rim matches the number of winding layers of the steel wire rope; Whether the working conditions of rope guide and rope guide meet the requirements;

5. Pulley. Whether the pulley is equipped with anti rope falling off groove device; Whether there are cracks, broken edges and excessive wear on the pulley rope groove and rim, and whether the pulley rotates flexibly.

6. Reducer. Whether there are abnormal sounds such as violent metal friction sound, vibration and shell radiation during reducer operation; Whether the shaft end is sealed well, whether the fixing bolt is loose or damaged; Whether the selection of reducer lubricating oil, oil level, operation of vertical reducer lubricating oil pump and open gear transmission lubrication meet the requirements.

7. Wheels. Whether the wheel tread and axle have fatigue cracks, and whether the wheel tread and axle wear exceed the standard. Whether rail gnawing occurs during operation. What is the cause of rail gnawing.

1. Compact structure, small volume, light weight, large in output torque.

2. High efficiency, low noise, small vibration.

3. To increase the transmission center distance, to reduce the gearbox height to meet the requirements of the operation mechanism.

4. Higher operation reliability and enhanced transmission power.

5. Long oil change period reduce the maintenance cost.

6. Speed Ratio range up to 400, meet the low speed working requirement.

We will contact you within 24 hours.

Experienced sales team can provide professional reply in time

Exclusive engineer can offer you the design within 24 hours

Euro Double Girder Crane for Inner Mongolia Energy Group Project

Zhonggong Group has Successfully Attended the CTT Expo2024

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition-copy-1715852535