Euro Double Girder Crane for Inner Mongolia Energy Group Project

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

Double girder overhead cranes are usually used in open warehouses or railways and other places to carry out common loading and unloading and material handling tasks. The double girder overhead crane is a heavy-duty bridge crane that is frequently used.

| overhead crane(5-50t) | Lifting Capacity | ton | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 | |

| Lifting speed | m/min | 11.5 | 8.5 | 7.9 | 7.2 | 6 | 6 | |

| Trolley travelling speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 | |

| Crane travelling speed | m/min | 70.6 | 70.6 | 74.3 | 75.1 | 64.9 | 58.5 | |

| Work class | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | ||

| Track type | P38 | P38 P43 | P43 | P43 | QU70 | QU80 |

| overhead crane(75-250t) | Lifting Capacity | ton | 75 | 100 | 125 | 160 | 200 | 250 |

| Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 | |

| Lifting height | m | 6~20 | 6~20 | 6~20 | 6~22 | 6~20 | 6~20 | |

| Lifting speed | m/min | 3.9 | 3.1 | 3.9 | 3.5 | 2.6 | 2.2 | |

| Trolley travelling speed | m/min | 31.3 | 33.6 | 33 | 40 | 32 | 32 | |

| Crane travelling speed | m/min | 61 | 61.8 | 62.3 | 68 | 48 | 50 | |

| Work class | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | ||

| Track type | QU100 | QU100 | QU100 | QU120 | QU120 | QU120 |

| overhead crane(300-450t) | Lifting Capacity | ton | 300 | 350 | 400 | 450 |

| Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 | |

| Lifting height | m | 6~24 | 6~24 | 6~30 | 6~30 | |

| Lifting speed | m/min | 2.4 | 2.2 | 2.6 | 2.1 | |

| Trolley travelling speed | m/min | 28 | 28 | 31 | 27 | |

| Crane travelling speed | m/min | 42 | 42 | 45 | 42 | |

| Work class | A3~A7 | A3~A7 | A3~A7 | A3~A7 | ||

| Track type | QU120 | QU120 | QU120 | QU120 |

Widely used for handling materials in industries' workshop and warehouse

Load Capacity can be up to 500t, the maximum span up to 35 m

Reduce the overall investment of the plant, improve production efficiency, reduce maintenance costs

save operating energy consumption, and obtain a better return on investment

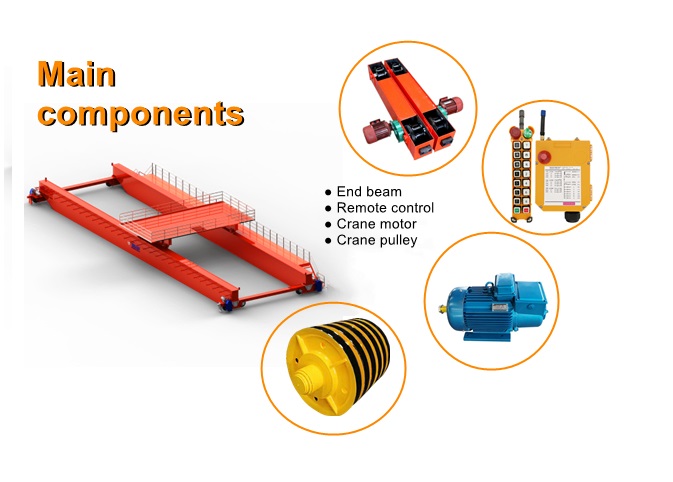

The double girder overhead crane is widely used for lifting heavy materials in plants, warehouse, and material stocks. It’s composed with Girder frame, Crane travel device, and the trolley with lifting and moving device. The trolley and hoist run on a rail installed on top of the bridge girders, and the double girder overhead crane can be either top running or under running in design. Assemble the moving table on the outside of the two main girder, one side is prepare for the assemble and maintenance the crane move device, and another side is prepare for the assemble of the trolley conductor device.

The double girder overhead crane is widely used for lifting heavy materials in plants, warehouse, and material stocks. It’s composed with Girder frame, Crane travel device, and the trolley with lifting and moving device. The trolley and hoist run on a rail installed on top of the bridge girders, and the double girder overhead crane can be either top running or under running in design. Assemble the moving table on the outside of the two main girder, one side is prepare for the assemble and maintenance the crane move device, and another side is prepare for the assemble of the trolley conductor device.

There are full field of view Cabin suspend under the main girder, there are joint control desk or single control box packed within the Cabin, assemble the sidelong ladder between the Cabin and moving table, The main girder joint with the two side end carriage which with the joint point in the middle.

With high speeds, extreme level of equipment utilization, high performance and high reliability, we offer a wide range of cranes for the metal production especially the steel production sector. The hazardous conditions of underground and open-cut mining require durable cranes can work stably and reliably in extreme environment. We provide customized crane solutions, to help customers get the best lifting way and increase the efficiency and safety.

We will contact you within 24 hours.

Experienced sales team can provide professional reply in time

Exclusive engineer can offer you the design within 24 hours

Euro Double Girder Crane for Inner Mongolia Energy Group Project

Zhonggong Group has Successfully Attended the CTT Expo2024

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition-copy-1715852535