Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

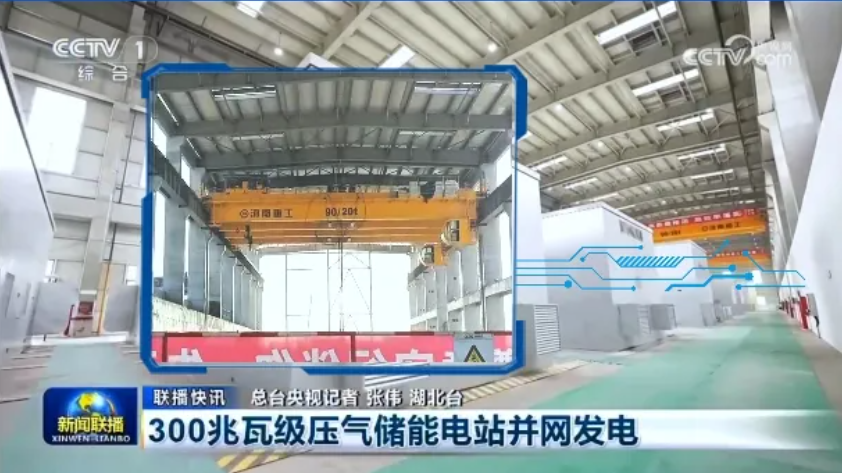

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

Shipbuilding is a complex and intricate process that demands precision, safety, and immense lifting power. Enter the Shipyard Gantry Crane – a colossal engineering masterpiece that looms over shipyards, orchestrating the ballet of assembling and maneuvering massive vessels. In this blog, we delve into the world of Shipyard Gantry Cranes, exploring their significance, components, applications, and the impact they've had on the maritime industry.

Shipyard Gantry Crane, often referred to as "Goliaths of the Dockyard," are purpose-built giants designed to handle the extraordinary demands of ship construction and maintenance. These cranes stand as towering sentinels in shipyards, armed with exceptional lifting capacity and an intricate system of pulleys, cables, and hydraulics that enable them to lift, move, and position ship components with precision.

Just like their counterparts in other industries, Shipyard Gantry Cranes feature girders that span the width of the ship. These girders support a trolley system, which holds the lifting mechanism and can traverse the length of the crane, enabling precise positioning. The heart of the crane, the lifting mechanism, includes a combination of winches, pulleys, and hoists. This arrangement provides the raw power required to lift ship components that often weigh hundreds of tons. To safely lift and maneuver ship components, specialized spreaders are employed. These devices securely grasp containers, sections of the ship's hull, or other components, ensuring stability during transport. Operated by skilled crane operators, the control cabin houses the controls for movement, lifting, and positioning. Modern versions may incorporate advanced technologies like cameras and sensors to aid operators in their tasks.

These cranes facilitate the assembly of vessels by lifting and positioning heavy sections, allowing for seamless integration of hull components, engines, and other crucial parts. During maintenance, inspection, or repairs, Shipyard Gantry Cranes hoist ships out of the water and onto dry land, providing easy access to underwater sections and enabling efficient maintenance work. In modern ports, these cranes are utilized to load and unload cargo containers from ships with exceptional precision and speed. Ship to shore gantry crane are also employed in offshore construction, assisting in the assembly of oil rigs, platforms, and other maritime structures.

The introduction of Shipyard Gantry Cranes has transformed shipbuilding and maritime logistics. With their ability to lift mammoth loads, expedite construction processes, and enhance safety, they've redefined the possibilities of shipbuilding. These cranes have enabled the construction of larger vessels, streamlined operations, and minimized downtime, contributing significantly to the growth and development of the maritime industry.

The Shipyard Gantry Crane stands as a testament to human ingenuity and engineering excellence. Its towering presence on the waterfront symbolizes the remarkable progress made in shipbuilding and maritime logistics. From the intricate mechanics that enable it to lift colossal ship components to its crucial role in modern shipyards, this crane has played a pivotal role in shaping the maritime landscape, ensuring that vessels of all sizes and types sail smoothly into the open seas.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259