Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

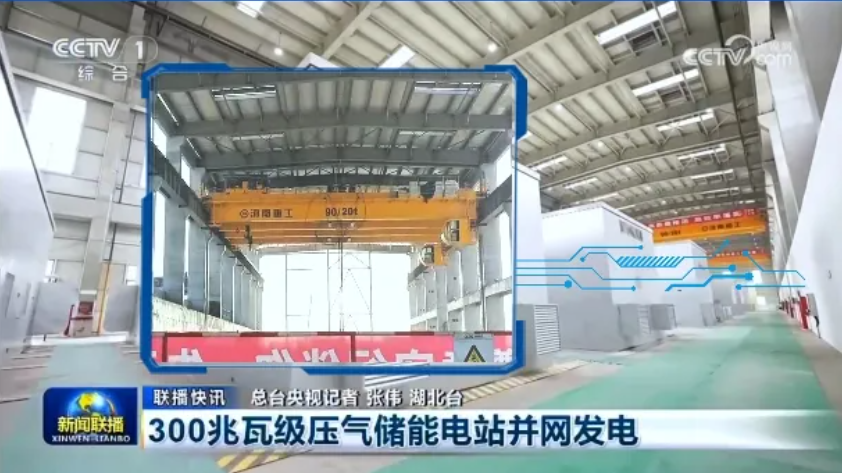

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

When it comes to heavy-duty lifting and precise maneuvering of massive loads, the engineering marvel known as the Girder Gantry Crane takes center stage. This industrial powerhouse has revolutionized the way we handle and transport heavy objects in a variety of sectors, from construction to manufacturing and beyond. In this blog, we'll delve into the intricate workings of the Girder Gantry Crane, its applications, benefits, and how it continues to shape modern industries.

At its core, a Girder Gantry Crane is a type of crane that straddles its workload using a pair of robust girders, which are essentially horizontal beams that provide the girder crane with stability and support. These girders are mounted on wheeled structures that allow the crane to move along a rail system or even rubber tires in certain configurations. The lifting mechanism typically consists of a hoist and trolley system that travels across the girders, providing the crane with vertical lifting capabilities and horizontal load movement.

Girder Gantry Cranes find themselves in various industrial sectors due to their versatility and impressive lifting capacity. In the construction domain, these cranes are essential for moving heavy building materials, placing large structural components, and aiding in the assembly of skyscrapers and bridges. They're equally indispensable in shipyards, facilitating the loading and unloading of ship cargo with ease. Moreover, manufacturing units rely on Girder Gantry Cranes for the seamless transportation of heavy machinery within factories. These cranes ensure precision and safety in moving components from one assembly point to another, contributing to streamlined production processes. The versatility of these cranes extends to the realm of logistics, where they are employed in warehouses and distribution centers for efficient movement and stacking of goods.

Girder Gantry Cranes boast remarkable lifting capacities, making them suitable for handling objects that are otherwise impossible to move manually. Thanks to their wheeled structure or rail system, these cranes can easily move along predetermined paths, providing exceptional flexibility in load transportation. The combination of horizontal and vertical movement mechanisms enables these cranes to precisely position heavy loads, contributing to enhanced accuracy during delicate operations. With safety being paramount in industrial operations, Girder Gantry Cranes and gantry girder are designed with safety features such as overload protection, emergency braking, and operator controls to ensure secure lifting practices.

As technology advances, Girder Gantry Cranes have also evolved to become smarter and more efficient. The integration of automation and remote control systems allows for seamless and precise control of these cranes, minimizing the need for human intervention in risky or intricate operations. Additionally, the utilization of sensors and real-time monitoring enhances safety by providing instant feedback on load conditions and potential issues.

The Girder Gantry Crane stands as a testament to human engineering prowess and innovation. Its ability to handle heavy loads with precision, its adaptability across diverse industries, and the continuous technological enhancements make it an indispensable asset in modern industrial landscapes. From towering skyscrapers to intricate manufacturing processes, the Girder Gantry Crane plays a pivotal role in shaping the world we live in today.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259