Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

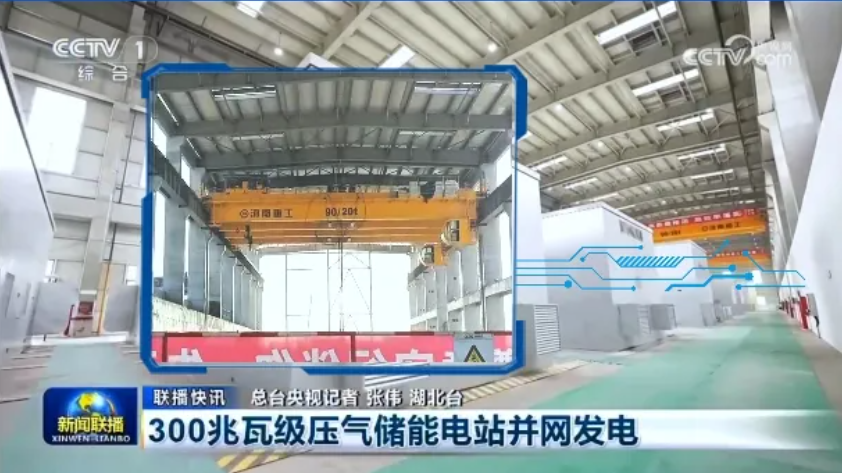

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

Check the connection between the metal structure of the tower crane and the electrical equipment casing. In TN-C-S system, the zero line should be separated into protective line PE and working zero line N. They should be separated at the driver's cabin control box or the ground distribution box and kept separated at all times.

Check the grounding resistance. If the measured grounding resistance is ≤10, the tower body embedded in the ground can be used for grounding. Otherwise, an independent grounding device should be set up for repeater grounding.

Verify the single-phase short-circuit current. Check whether there is a short-circuit protection device in the total current loop of the tower crane, whether the selection and setting meet the regulations, and record the rated current of the fuse or the action setting current of the circuit breaker. Calculate or quantitatively test the impedance of the phase-zero loop to obtain the single-phase short-circuit current, which should be greater than 4 times the rated current of the fuse or 1.5 times the action setting current of the circuit breaker.

Conduct an on-site test of the leakage protector of the gantry crane. If the impedance of the phase-zero loop fails calibration and protective grounding is difficult to meet the requirements, the TT system should be adopted. The measured grounding resistance should be ≤4, but an effective leakage protection device must be set up. Repeatedly press the test button 3 times to confirm the reliable action of the leakage protector. The load switch should be repeatedly turned on and off 3 times without any malfunctions.

To properly inspect a gantry crane, not only should the standardized inspection method be understood, but also targeted inspection methods should be adopted according to specific inspection content and environmental factors. The inspection of gantry cranes includes two parts: mechanical and electrical inspections. The mechanical inspection methods are diverse and include the detection of the mid-span upper deflection of the main beam and the local warping of the belly plate of the main beam, among other things.

As for the inspection method for the mid-span upper deflection of the main beam of the gantry crane, the method is to use the cushion to level the main beam and ensure that the elevation difference of the upper cover plates at both ends of the seat plate is ≤2mm. If it is a double main beam structure, the cushion should be placed directly under the main beam seat plate; if it is a single main beam structure, the support centerline of the cushion should be placed 700mm outside the main beam seat plate.

The other is the inspection of the protective grounding of the gantry crane. On the one hand, it is necessary to check whether the connection between the metal structure of the tower crane and the electrical equipment shell is good.

Not only that, but also check whether there is a short-circuit protection device in the total current circuit of the gantry crane tower crane, whether the selection and setting meet the regulations, record the rated current of the fuse or the setting current of the circuit breaker action; calculate or quantitatively test the phase zero circuit impedance, and calculate Single phase short circuit current.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259