Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

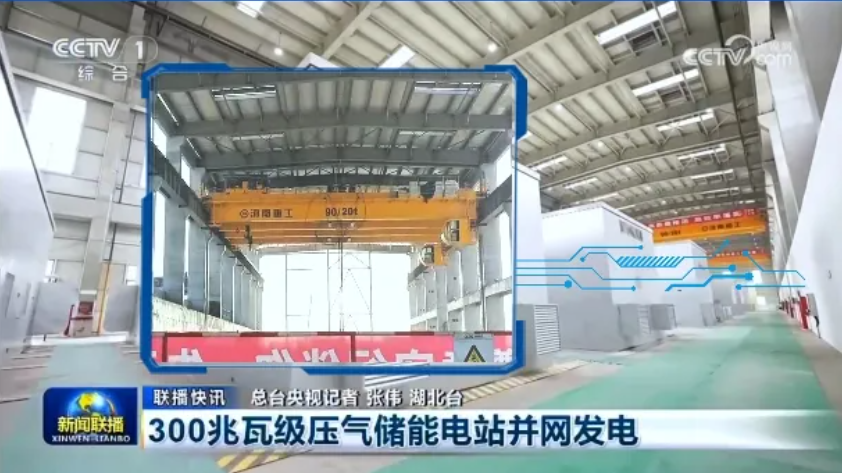

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In the ever-evolving world of manufacturing, technology continues to reshape processes and increase efficiency. One such innovation that has made a significant impact on assembly line operations is the electric chain hoist. This powerful tool has revolutionized painting assembly lines, offering enhanced safety, precision, and productivity like never before. In this blog, we will explore the game-changing benefits of electric chain hoists and how they have transformed the painting assembly line landscape.

Prioritizing safety is a crucial aspect of any manufacturing operation. Electric chain hoists have taken safety to a whole new level in painting assembly lines. Equipped with advanced features like overload protection, emergency stop buttons, and limit switches, these hoists ensure workers can undertake their tasks with minimal risk. Additionally, the precise control offered by electric chain hoists reduces the chances of accidents, steering assembly lines towards a safer work environment.

When it comes to painting assembly lines, precision is of paramount importance. Electric chain hoist offer unparalleled accuracy and control in lifting and moving heavy loads during the painting process. Their variable speed control, combined with smooth starts and stops, enables workers to position the items precisely, ensuring a flawless finish. The ability to adjust lifting speeds and direction effortlessly vastly improves the overall quality of the assembly line's painting process.

Electric chain hoists have drastically boosted productivity levels in painting assembly lines. Their robust lifting capabilities, coupled with faster lifting and lowering speeds, allow for quicker movements of heavy items that are to be painted. This, in turn, reduces the overall assembly time, streamlining the production process. The elimination of manual lifting also minimizes fatigue among workers, enabling them to perform at an optimal level consistently.

Painting assembly lines often require flexible equipment that can accommodate different sizes and weights of items. Electric chain hoists fulfill this requirement effortlessly. With their adjustable lifting capacities, they can cater to various product dimensions without compromising on safety or efficiency. This versatility makes electric chain hoists a valuable asset in painting assembly lines, adaptable to the changing needs of the manufacturing environment.

With the multitude of benefits they bring, may seem that electric chain hoists and hoist trolley systems would come with a hefty price tag. However, these technological wonders have proven to be a cost-effective investment. By increasing productivity, reducing assembly time, and minimizing the risk of accidents, these hoists save both time and money in the long run. Moreover, the durability and reliability of electric chain hoists translate into reduced maintenance costs, further contributing to their overall economic advantage.

Electric chain hoists have revolutionized the way painting assembly lines operate. From improved safety measures and enhanced precision to increased productivity and cost-effectiveness, these hoists have become an invaluable asset in manufacturing environments. Their versatility and adaptability make them indispensable tools for painting assembly lines, propelling the industry towards greater efficiency and success. Embracing this transformative technology can unlock a multitude of benefits and empower businesses to paint a brighter future.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259