Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

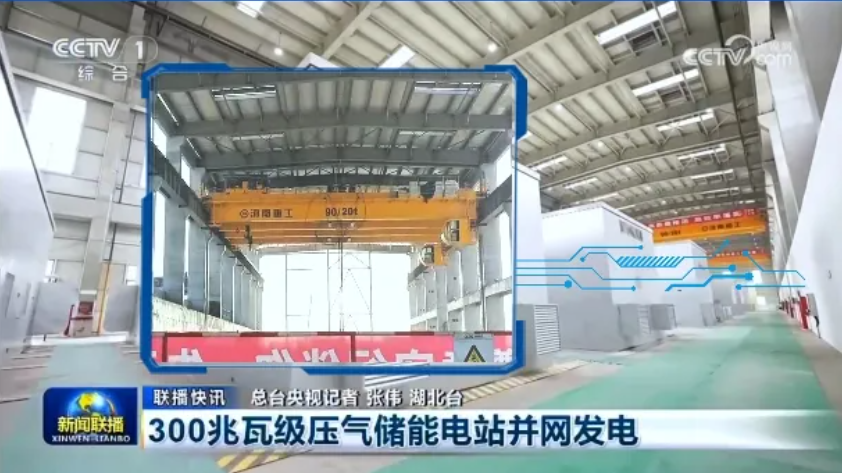

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

The electric chain hoist, also known as loop chain electric elevator or electric inverted chain, has a lifting capacity of 0.1 to 60 tons and a lifting height of 4 to 120 meters.

It combines the advantages of wire rope electric hoist and manual hoist, with more advanced and rational design. Therefore, electric chain hoist is beautiful in appearance, small in size, light in weight, high in mechanical strength, great in toughness, safe and reliable to use, easy to maintain, easy to operate, and durable. It is widely used in modern industrial production lines, assembly lines, assembly machines, logistics and transportation, and other occasions such as mechanical manufacturing, electronics, automobiles, shipbuilding, and high-tech industrial parks.

Its excellent quality is especially shown in operations in small working spaces such as warehouses, docks, ingredients, suspension baskets, and narrow spaces.

The electric chain hoist is very convenient for lifting heavy objects, handling, repairing equipment, and transporting goods. It can also be installed on suspended I-beams, curved tracks, swing arm guide rails, and fixed suspension points to lift heavy objects.

Shell: The shell is lightweight and sturdy, with a high heat dissipation rate, and a fully sealed design suitable for use in harsh working conditions.

Phase reverse protection device: It is a special electrical device. When the power supply wiring is incorrect, the control circuit cannot work.

Limit switch: This kind of chain hoist has limit switch devices when lifting and lowering heavy objects, which automatically stop the motor to prevent the chain from exceeding and ensure safety.

Voltage converter: When there is leakage when operating, it can prevent accidents from happening.

Brake device: This device can brake instantly when the power is cut off.

Chain bag: lightweight, beautiful, and durable.

Chain: Use FEC80 heat-treated alloy steel chain.

In order to ensure normal operation, it must be load-tested. It is not allowed to work when powered on before installation and commissioning, and can only be powered on for load testing after installation and commissioning are completed.

When operating the electric chain hoist, load testing is often required. The general practice is to raise the set rated load for trial loading, carefully observe the use of the electric hoist, recognize its load value at any time, identify the rated load, and judge whether the electric chain hoist meets the requirements.

The lubricating oil used must be clean and free of impurities. When applying lubricating oil, it should be evenly applied, with moderate oil quantity. Too little or too much oil will cause serious consequences. Because oil has a high density, applying too much will cause poor heat dissipation and shorten the service life of the electric chain hoist. Moreover, applying too much lubricant will cause more dust or dirt to adhere to the outer layer, causing greater trouble for future cleaning.

It is also necessary to regularly check the bolts and power cables of the fixed mini hoist, and timely remove the dust and corrosive liquid accumulated on the cable.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259