Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

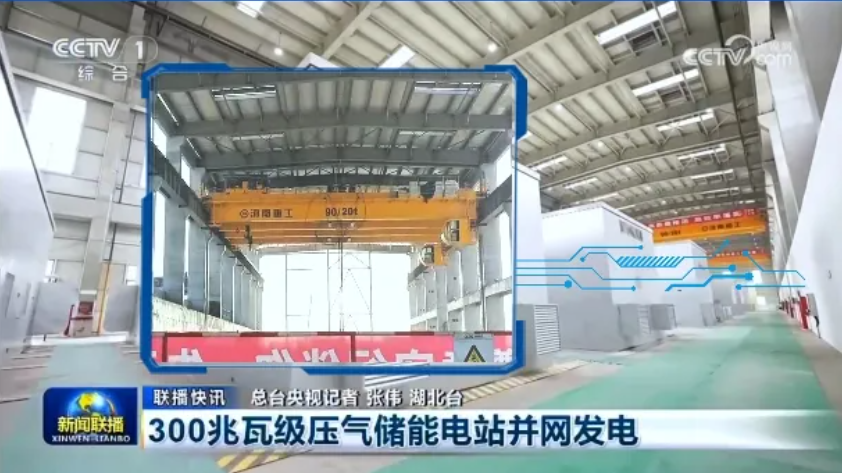

An overhead crane is a lifting equipment that lifts materials over workshops, warehouses, and material yards. Its two ends are located on tall cement pillars or metal supports, resembling a bridge. The bridge frame of the overhead crane runs longitudinally along the rails on both sides of the elevated track, which can fully utilize the space under the bridge to lift materials without being obstructed by ground equipment. It is the most widely used and largest quantity lifting machinery.

A bridge-type crane running on the elevated rail is also called an overhead crane. The bridge frame of the overhead crane runs longitudinally along the rails on both sides of the elevated track, and the hoist trolley runs transversely on the rails on the bridge frame to form a rectangular working range. It can fully utilize the space under the bridge to lift materials without being obstructed by ground equipment. This type of crane is widely used in indoor and outdoor warehouses, factories, terminals, and open storage yards. In the steel and chemical industries, the use of explosion proof overhead crane has become particularly prevalent, as it significantly reduces safety risks associated with flammable and hazardous materials. Overall, overhead cranes play a vital role in different aspects of industrial production, making them indispensable equipment across various industries.

The overhead crane is generally composed of a bridge (also called a large car), a hoisting mechanism, a trolley, a large car transfer mechanism, a control room, a small car conductive device (auxiliary sliding wire), and a total power supply conductive device (main sliding wire), etc.

Bridge

The bridge is the basic component of the overhead crane, which is composed of main beams, end beams, and runway beams. The main beam spans the space in the bay and has structure forms such as a box-type, truss-type, web plate, and circular tube. The end beams are connected to the two ends of the main beam, and walkways with safety railings are installed on both sides of the main beam. The large car transfer mechanism is installed on the walkway on the side of the cab, and the auxiliary sliding wire device for supplying power to the electrical equipment of the small car is installed on the walkway on the other side. The guide rails are installed above the main beam for the movement of the hoist trolley. The entire overhead crane moves on the rails in the length direction of the workshop under the dragging of the large car transfer mechanism.

Large car operating mechanism

The large car operating mechanism is composed of a large car dragging motor, a transmission shaft, a reducer, car wheels, and brakes. The driving methods are centralized driving and separate driving.

Trolley operating mechanism

The crane trolley is placed on the guide rail of the bridge frame and can move along the width direction of the workshop. The trolley is mainly welded by steel plates and composed of a trolley frame and its operating mechanism and hoisting mechanism. The running mechanism of the trolley is composed of a trolley motor, a brake, a coupling, a reducer, and car wheels. The trolley motor drives the active wheel of the trolley through a reducer, and the trolley moves along the guide rail. The transmission form of the trolley running mechanism has two types: one type is the reducer in the middle of the two active wheels, and the other is the reducer installed on one side of the trolley. The reducer installed in the middle of the two active wheels evenly distributes the torque borne by the transmission shaft, while the reducer installed on one side of the trolley makes installation and maintenance more convenient.

Hoisting mechanism

The hoisting mechanism is composed of a hoisting motor, a reducer, a drum, and a brake. The hoisting motor is connected to the reducer through a coupling and a brake wheel. The output shaft of the reducer is connected to the drum that winds the steel wire rope. The other end of the steel wire rope is equipped with a hook that moves up and down with the winding or releasing of the steel wire rope on the drum. For cranes with lifting weights of 15t or more, there are two sets of hoisting mechanisms, the main hook, and the auxiliary hook.

In summary, heavy objects can be lifted up and down with the rotation of the drum, moved left and right along the width direction of the workshop with the trolley, and moved forward and backward along the length direction of the workshop with the large car. This can achieve the movement of heavy objects in three directions of vertical, horizontal, and longitudinal, move heavy objects to any position in the workshop, and complete lifting and transportation tasks.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259