Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

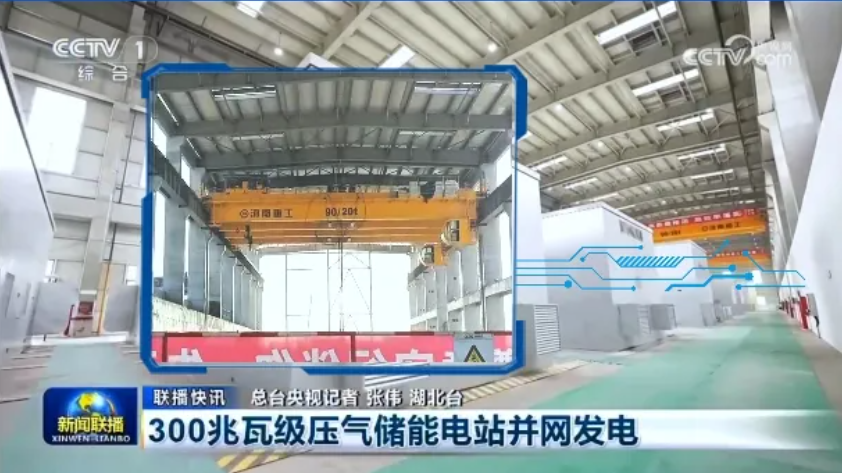

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In the fast-paced world of automotive manufacturing, efficiency and precision are paramount. L Type Gantry Cranes have emerged as indispensable tools in this industry, playing a crucial role in streamlining manufacturing processes and ensuring the seamless flow of materials. In this blog post, we'll explore how L Type Gantry Cranes contribute to the optimization of workflows, safety, and overall productivity in the automotive sector.

L Type Gantry Cranes are renowned for their ability to handle heavy loads with precision and speed. In the automotive industry, where components and assemblies vary greatly in size and weight, these cranes provide a versatile solution for moving materials across the manufacturing floor. From lifting engine blocks to positioning chassis components, L Type Gantry Crane offer the necessary flexibility to accommodate diverse production requirements.

Safety is a top priority in automotive manufacturing, and L Type Gantry Cranes are designed with this in mind. With advanced features such as ergonomic controls and safety sensors, the industrial gantry crane minimize the risk of accidents and injuries on the factory floor. Operators can navigate loads with precision, ensuring that materials are placed accurately without compromising the well-being of workers or the integrity of the automotive components being handled.

In the automotive industry, where assembly lines operate with clockwork precision, any disruption can have significant consequences. L Type Gantry Cranes contribute to the seamless functioning of assembly lines by efficiently transporting components to the required workstations. Their ability to cover large areas and reach diverse points on the manufacturing floor ensures that materials are delivered promptly, preventing bottlenecks and delays in the production process.

L Type Gantry Cranes are known for their adaptable design, making them ideal for facilities with varying layouts and space constraints. In the automotive industry, where every square foot of space is valuable, these cranes offer a solution that maximizes the use of available floor area. Their ability to move loads horizontally and vertically allows for efficient utilization of workspace, contributing to an organized and streamlined manufacturing environment.

As the automotive industry embraces automation, L Type Gantry Cranes seamlessly integrate into smart manufacturing systems. They can be equipped with advanced technologies such as programmable logic controllers (PLCs) and automation software, allowing for precise control and coordination within the manufacturing process. This integration further enhances efficiency and reduces the margin of error in material handling tasks.

In conclusion, L Type Gantry Cranes have become integral to the success of the automotive industry by streamlining manufacturing processes. From optimizing material handling efficiency to enhancing safety protocols and facilitating the integration of automation technologies, these cranes contribute significantly to the overall productivity and competitiveness of automotive manufacturing. As the industry continues to evolve, L Type Gantry Cranes will undoubtedly play a pivotal role in shaping the future of efficient and innovative automotive production.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259