Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

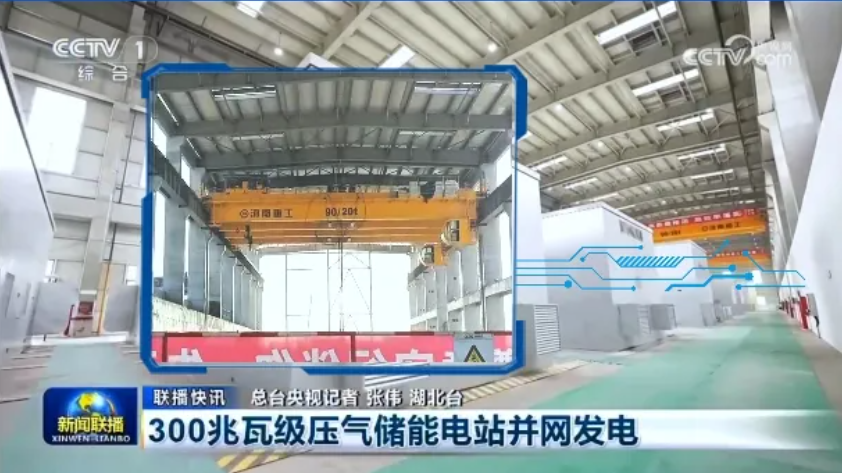

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In the realm of mold manufacturing, precision is everything. The ability to create molds that meet exact specifications is crucial for industries such as automotive, aerospace, and consumer goods. One technology that has revolutionized the mold manufacturing industry is the hydraulic gantry crane. In this blog post, we will explore the benefits of hydraulic gantry cranes in enhancing the efficiency and accuracy of the mold manufacturing process.

Hydraulic gantry cranes, also known as gantry systems, are heavy-duty lifting equipment used in various industries. Unlike traditional cranes, hydraulic gantry cranes offer superior control, precision, and stability. Equipped with hydraulic cylinders, these cranes can lift and move heavy loads with utmost accuracy.

When it comes to mold manufacturing, safety is paramount. Hydraulic gantry crane provides a high level of safety during the lifting and moving processes. Their precise control systems allow for smooth and controlled movements, significantly reducing the risk of accidents. Moreover, hydraulic gantry cranes can handle heavy loads with ease, making mold transportation more efficient and time-saving.

Accuracy is crucial in mold manufacturing, especially when it comes to aligning and positioning intricate components. Hydraulic gantry cranes excel in precise positioning, ensuring that molds are perfectly aligned during assembly. This level of accuracy minimizes the need for manual adjustments, resulting in faster production times and improved overall quality.

Hydraulic gantry cranes offer a high degree of flexibility and adaptability in mold manufacturing processes. They can be easily customized to fit specific requirements, such as different mold sizes and shapes. This versatility allows manufacturers to optimize their operations to meet the ever-changing demands of the industry.

In mold manufacturing, working with specialized materials is not uncommon. Hydraulic gantry cranes are capable of handling a wide range of materials, including heavy metals and delicate composites. Their hydraulic lifting systems provide the necessary strength and stability to lift and move these specialized materials safely. This ability to handle diverse materials further enhances the efficiency and precision of the manufacturing process.

In the competitive world of mold manufacturing, precision is the key to success. Hydraulic gantry cranes have proven to be invaluable tools in enhancing the efficiency, accuracy, and safety of the mold manufacturing process. With their ability to provide precise positioning, enhanced safety features, and adaptability to specialized materials, hydraulic gantry cranes have become an indispensable asset for manufacturers seeking to deliver high-quality molds on time and within budget. Embracing this advanced technology can undoubtedly boost productivity and set businesses apart in the ever-evolving mold manufacturing industry.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259