Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

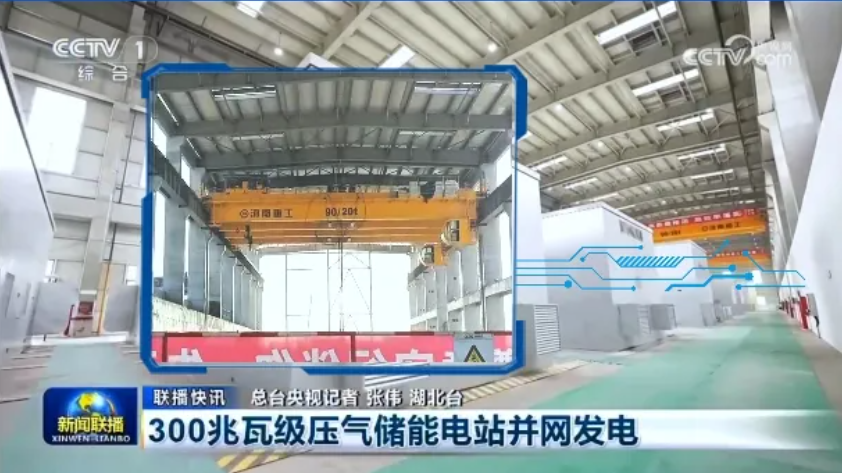

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In today's age of global trade and e-commerce, the warehousing industry plays a critical role in ensuring the smooth movement of goods across continents. Within this sector, container handling cranes have emerged as an essential tool for efficient operations. In this blog post, we will explore the significance of container handling cranes and how they have revolutionized modern warehousing.

Container handling cranes, also known as gantry cranes or ship-to-shore cranes, are large machines used for the movement of containers within ports and warehouses. These cranes are characterized by their towering height, allowing them to lift heavy loads and reach across multiple container stacks. Their immense strength and precise maneuverability make them a crucial component of modern warehousing operations.

One of the primary contributions of container handling cranes is their ability to streamline warehouse operations. By efficiently lifting and moving containers, these cranes reduce handling time and minimize the risk of delays. This leads to increased productivity and throughput, enabling warehouses to meet demands effectively. The utilization of container handling cranes ensures that goods are handled swiftly, allowing for seamless logistics management.

The implementation of container handling cranes significantly enhances safety within the warehousing environment. Traditionally, manual handling of containers involved significant physical exertion, posing a high risk of injuries. With the advent of container lifting crane, the need for manual lifting is eliminated, minimizing the chances of accidents. Additionally, container handling cranes are equipped with advanced technology, such as anti-sway systems, which further reduce the possibility of human error during lifting operations.

Container handling cranes are designed to handle various container types and sizes, including standard twenty-foot and forty-foot containers, as well as specialized containers such as flat racks and open tops. The flexibility of mobile container crane allows warehouses to efficiently manage diverse cargos, including perishable goods, hazardous materials, and oversized containers. This adaptability ensures that different types of containers can be seamlessly transferred, contributing to the overall efficiency and effectiveness of warehousing operations.

As technology continues to evolve, container handling cranes are expected to undergo further advancements. Automation and robotics are already making their way into the warehousing sector, and container handling cranes are not exempt from these developments. The integration of artificial intelligence and machine learning algorithms could improve the accuracy and speed of crane operations, further optimizing efficiency within the warehouse. Moreover, the utilization of sensors and Internet of Things (IoT) technology may enable real-time monitoring, predictive maintenance, and enhanced safety measures.

In conclusion, container crane plays a vital role in modern warehousing operations. These powerful machines streamline operations, maximize efficiency, enhance safety, and increase adaptability. With further advancements on the horizon, such as automation and AI, the future of container handling cranes looks promising. As the warehousing industry continues to evolve, it is evident that container handling cranes will remain a cornerstone of efficient logistics management.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259