Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In the fast-paced world of modern manufacturing, packing processes play a crucial role in ensuring products reach consumers in pristine condition. Efficiency, precision, and safety are paramount in these operations, and the machinery used can significantly impact these factors. One such technological marvel making waves in the packing industry is the Electric Chain Hoist. This versatile tool has become an indispensable asset in the processing and assembly lines of general manufacturing, packing, and painting.

The electric chain hoist is designed to lift light and small-sized materials or goods with ease. Its robust construction and advanced engineering make it an ideal choice for applications where precision and reliability are non-negotiable. The hoist is not only capable of fixed suspension use but can also be seamlessly integrated with an electric monorail trolley and a hand push/pull monorail trolley, enhancing its versatility in diverse packing scenarios.

Enhanced Efficiency

The electric chain hoist significantly improves the efficiency of packing processes. Its swift lifting capabilities allow for faster handling of materials, reducing downtime and increasing overall productivity. In a competitive market, time is money, and the electric chain hoist ensures every moment is utilized optimally.

Precision and Control

Packing processes demand precision to avoid damage to fragile goods. The electric chain hoist provides operators with precise control over lifting operations, ensuring delicate items are handled with care. The ability to make micro-adjustments during the lifting process contributes to the overall quality of packing.

Versatility in Movement

The hoist's compatibility with electric monorail trolleys and hand push/pull monorail trolleys allows for seamless movement within the packing facility. This adaptability ensures that the hoist can be utilized in various areas of the assembly line, catering to the dynamic needs of modern packing processes.

Safety Features

Safety is a top priority in any manufacturing environment. Electric chain hoists come equipped with advanced safety features such as overload protection and emergency braking systems. These features not only protect the goods being lifted but also safeguard the operators and other personnel working in the vicinity.

Space Optimization

The compact design of electric chain hoists and hoist trolley systems makes them ideal for packing facilities where space optimization is crucial. Whether in tight storage spaces or overhead assembly lines, the hoist's design allows for efficient use of available space without compromising on performance.

As modern packing processes continue to evolve, the role of electric chain hoists becomes increasingly significant. Their ability to enhance efficiency, provide precision and control, offer versatile movement options, incorporate advanced safety features, and optimize space makes them indispensable in the dynamic world of manufacturing. Investing in electric chain hoists is not just a step towards modernization; it's a strategic move towards achieving excellence in packing processes.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

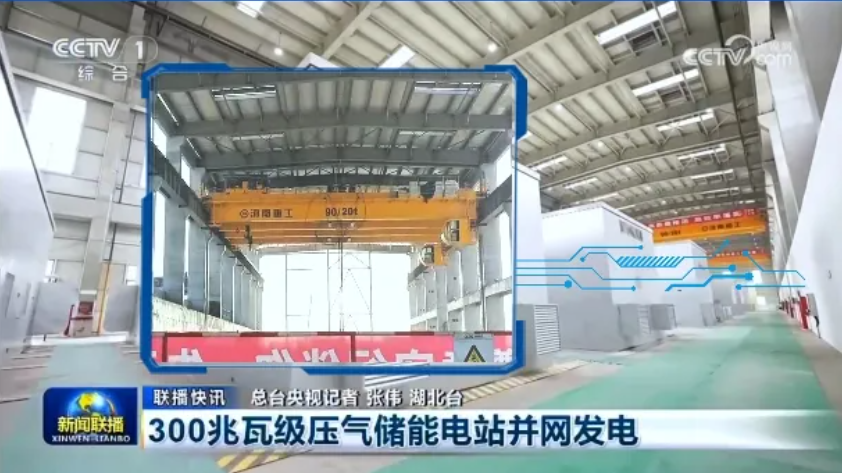

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259