Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

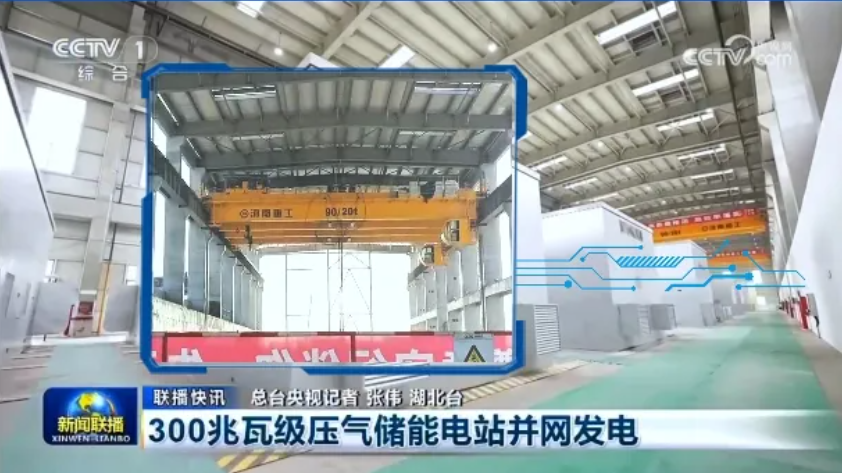

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

The squeezing accidents of EOT crane occur in the following three situations:

Such accidents mostly occur between the operating EOT crane or rotating EOT crane and the surrounding fixed objects. For example, the squeezing between the end beams of bridge EOT cranes and the columns and walls of surrounding buildings, and when tower EOT crane or mobile EOT crane rotates, the squeezing between their tails and other facilities.

Most accidents are caused because the space is small, or because the victim is in a blind spot in the driver's field of vision, or because of the driver's lack of observation. Therefore, there must be a proper distance between the EOT crane and the fixed objects, at least 0.5m apart, and no one should pass through during operation.

In this regard, first of all, the site should be reasonably arranged and heavy objects should be stacked. Goods should be stacked with appropriate clearances, and huge components and goods that are prone to rolling and overturning should be reasonably stacked for easy handling.

Secondly, choose slings and rigging suitable for the cargo to be hoisted, and tie and hang them reasonably to avoid rotating or falling off in the air. It is forbidden to directly drag the rotating heavy objects by hand, and the signal commander must follow the original hoisting plan.

For example, accidents occur when maintenance staff are squeezed between the automobile EOT crane turntable and other components. Among the material elevators, construction elevators have more problems, mainly due to incomplete protective devices. For example, there is no rising limiting stoppers, no protective railings or no protective doors.

The protective measures are: the position where staff operate the winch should be safe; if there is no closed cage, the passage should be closed to prevent people from passing; the entrance of the passage should be equipped with protective railing; when the maintenance work is carried out close to the upper limit device, attention should be paid to prevent head bumping; when work in the pit, pay attention to the falling of bridge box and counter weight of EOT crane to avoid accidents.

The operation, inspection, and maintenance work of EOT crane motor are mostly carried out in a high altitude. Ladder, railing, and platform are working devices and safety protection facilities on the EOT crane.

At the above-mentioned operating locations, platforms with guard rings and railing must be installed in accordance with regulations to prevent personnel from falling; when bridge boxes and cages are in operation, be careful not to overload; crane brakes and load-bearing components must meet safety requirements; falling prevention devices must be reliable; electrical equipment must have safety devices and be inspected regularly to prevent accidents.

Our company is home to the brand of "Yuzhong", and we provide material handling solutions for more than 1,000 well-known international companies, including Harbin Iron and Steel Group, PLA 4808 Plant, Shougang Group, Baosteel Group, China National Erzhong Group, Shenyang Heavy Electric Machinery Plant, Sinopec Qilu Co., Ltd., China YTO Group Corporation, China Gezhouba (Group) Corporation, Beijing Metallurgical Research Institute, etc. With strong strength, we also supply products to Russia, Japan, Zambia, Pakistan, Mongolia, Vietnam, South Korea, and Southeast Asia in the international market. If you have any needs, please feel free to consult us.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259