Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

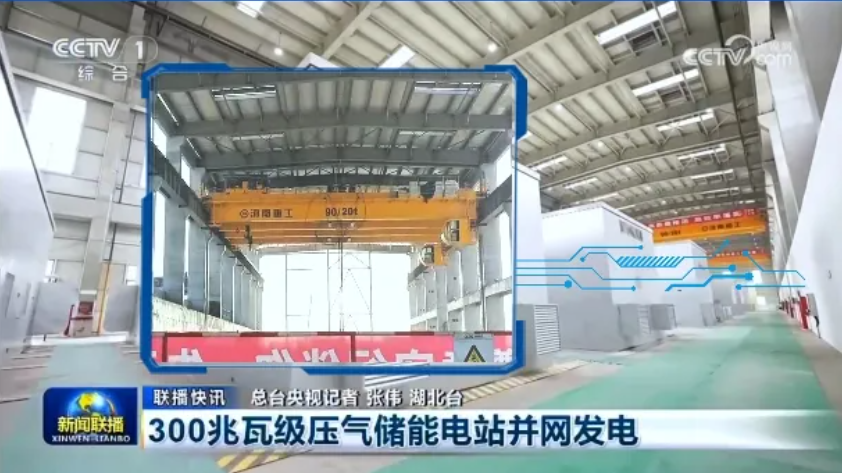

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

In today's fast-paced world, where global trade and commerce are at their peak, shipbuilding has become an indispensable industry. Building sturdy vessels that can traverse treacherous waters is a challenging task that demands utmost accuracy and efficiency. Dockside logistics play a crucial role in seamless shipbuilding, and one of the essential tools in this process is the shipbuilding gantry crane.

Shipbuilding gantry cranes are massive mechanical structures used for lifting heavy loads during the construction of ships. These cranes are usually installed in shipyards and provide the necessary support to assemble various parts of a ship. With their significant load-bearing capacity and versatility, shipbuilding gantry cranes have revolutionized the shipbuilding industry, making it possible to construct larger and more complex vessels than ever before.

The use of shipyard gantry crane brings numerous benefits to the dockside logistics of shipbuilding operations. Firstly, these cranes significantly reduce manual labor requirements by automating the lifting and positioning of heavy ship components. This not only speeds up the construction process but also minimizes the risks associated with manual handling.

Moreover, shipbuilding gantry cranes offer enhanced safety features such as load monitoring systems, anti-sway technology, and precise control mechanisms. These features ensure that each operation is carried out with utmost precision, reducing the chances of accidents and mishaps during the shipbuilding process.

Seamless shipbuilding heavily relies on maximizing productivity while minimizing costs. Shipbuilding gantry cranes contribute to this objective in several ways. Firstly, their efficient lifting mechanisms enable swift and precise positioning of ship components. This saves valuable time, allowing shipyards to complete projects within tight deadlines.

Additionally, shipbuilding gantry cranes optimize the use of available space in shipyards, especially when constructing large vessels. These cranes can move along rails, providing flexibility in reaching different sections of a ship under construction. By efficiently using space, shipbuilding gantry cranes help shipyards accommodate multiple ships simultaneously, thus enhancing productivity and cost-effectiveness.

Shipbuilding gantry cranes are versatile machines capable of handling various shipbuilding tasks. They can lift and position heavy parts such as hull sections, machinery modules, and superstructures with utmost precision. The ability to handle these complex tasks reduces the dependency on manual labor and enables shipyards to assemble ships more efficiently.

The shipbuilding industry is continually evolving, driven by technological advancements and the need for increased productivity. In the future, we can expect even more innovative shipbuilding gantry cranes, equipped with advanced automation systems and artificial intelligence.

As the demands of the shipbuilding industry continue to grow, the role of shipbuilding gantry cranes in dockside logistics will become increasingly crucial. These cranes have proven their worth by revolutionizing the efficiency, safety, productivity, and cost-effectiveness of shipbuilding operations. With their ability to handle complex tasks and adapt to unique requirements, shipbuilding gantry cranes are undoubtedly a game-changer in the seamless shipbuilding process.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259