Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

No. 6, Crane Industrial Park, Changyuan Town, Xinxiang City, Henan Province, China

Henan Zhonggong Group

Henan Tosta Machinery Co., Ltd.

Gantry Crane

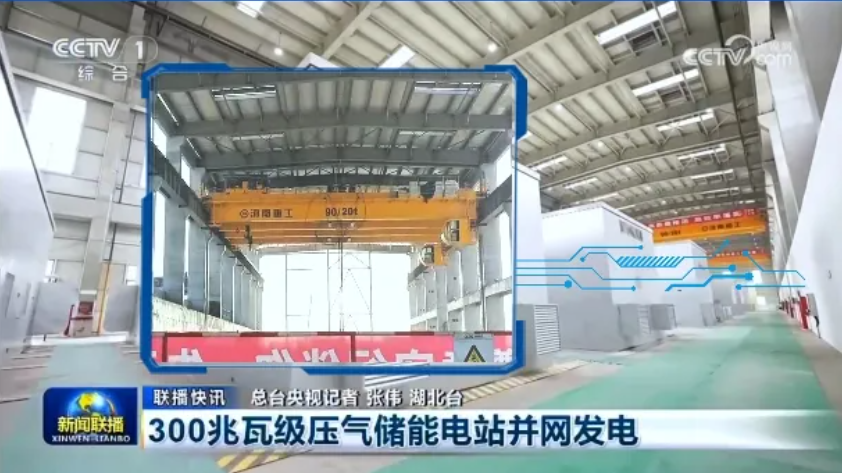

Overhead Crane

Light Crane

Port & Container Crane

Launching Gantry Crane

Hoist & Crane Trolley

Crane Components

Electric Winch Overview

EOT Crane

Overhead cranes in factories should not be mechanically lifted due to the narrow clearance between the track top and the lower chord of the roof truss, and the large size and weight of the crane. Small and medium-sized overhead cranes are often installed and lifted as a whole with a single mast, which can improve work efficiency, shorten construction period, reduce high-altitude operations, and follow the construction process below.

Mast height: The maximum height of the mast is the height from the ground to the roof panel minus the operating space between the top of the mast and the roof panel, and the height of the mast base. The minimum height should meet the lifting height requirements.

Mast position: As the mast needs to be erected at the center of gravity of the overhead crane between the two main beams, the trolley must be offset, and the mast should also deviate from the center line of the factory. The offset should be calculated based on the weight of the crane, the weight of the trolley, and the offset distance of the trolley.

Mast base treatment: The mast base should be compacted and leveled, and two or more sleepers should be laid. If necessary, steel rails or I-beams can be added between the two layers of sleepers. The area of the laying should be calculated based on the ground bearing capacity to ensure that the ground can withstand the axial pressure of the mast.

Mast erection method: The mast can be erected with a moving crane, or by using the factory crane beam or an auxiliary mast. When using the factory crane beam to erect the mast, the transverse horizontal force of the beam must be calculated to ensure that it does not exceed 1/20 of the rated lifting capacity of the overhead crane within the span, which is the sum of the maximum lifting weight of the crane and the weight of the trolley.

When erecting the mast, the cable wind rope of the mast should be temporarily tied to the lower chord of the roof truss close to the mast in advance. After the mast is hoisted to the designated position, all the wind ropes should be tied tightly at the top of the mast and tightened on the ground. If individual cable wind ropes cause the roof truss chord to lift or tilt, the mast should be temporarily tied with a cable wind rope to adjust the fixed cable wind rope to the appropriate position before releasing the temporary cable wind rope.

Hang the pulley group and set up a winch: For medium and small overhead cranes, two pulley groups can generally be hung, and two winches can be used to lift them. The distance between the winch and the center of the mast should be greater than the length of the mast. The winch can be fixed to the column in the factory, but protective measures like wooden blocks should be placed at the binding point.

The main beam and trolley of the overhead crane are transported to the lifting position for assembly. After the main beam assembly is completed, the overhead crane trolley is placed on the trolley track and tightly bound to the main beam.

For overhead cranes below 50t, only two sets of pulley groups are needed, and the cross-binding method is generally used. The method is to hang the lifting pulley group with the lifting ear of the mast facing the direction of the end beam of the overhead crane. The running rope passes through the fixed pulley on the top of the mast and goes down to the guiding pulley at the bottom and then leads to the winch. The running rope is sequentially arranged. On one side of the main beam, a binding rope passes through two slabs in the open hole of the beam walking platform for cross-binding. The binding rope is in a transverse "∞" shape, commonly known as the "8" method.

Overhead crane spare parts are highly versatile and can be used in various scenarios to resolve equipment issues. In instances where the effective height of the mast is insufficient, a practical solution is to tie the moving pulley group of the lifting arm truck to the inside of the main beam of the crane. With a cross beam erected on the top of the beam, two lifting ropes can be tied to the ends, and subsequently wound into the moving pulley through the bottom of the main beam. This is a cost-effective and relatively simple way to increase the effective height of the mast without requiring significant alterations to the crane equipment.

Lift the overhead crane 0.3-0.5m off the ground. If there are no abnormal phenomena after 10 minutes, shake the overhead crane to test the reliability of the winch, the mast, the cable wind rope, and the ground anchor, etc. If everything is normal, continue with the lifting operation.

Lift the overhead crane about 2.5m off the ground, stack the sleepers under the crane, make the crane rest on the sleepers, and then install the control room on the main beam. After installing the control room, adjust the position of the trolley. The position is calculated to balance the two sides of the mast hanging point.

Then lift the overhead crane a short distance away from the sleepers and carefully adjust the position of the trolley. After confirming the balance, fix the trolley again. Check other lifting facilities, confirm their safety and reliability, and then lift the overhead crane.

Henan Zhonggong Group Invites You to Attend the 9th Changyuan (China) International Hoisting Machinery Exhibition

Henan Zhonggong Group Helped CEEC Project Creating a Number of World Records

Henan Zhonggong Group Manufactures 130 ton Double Girder Overhead Cranes-copy-1713231259